Name: ZENYER Visual Shell Inspector

Product Code: 410S/430S

Capacity: 10,000~30,000 eggs/hour

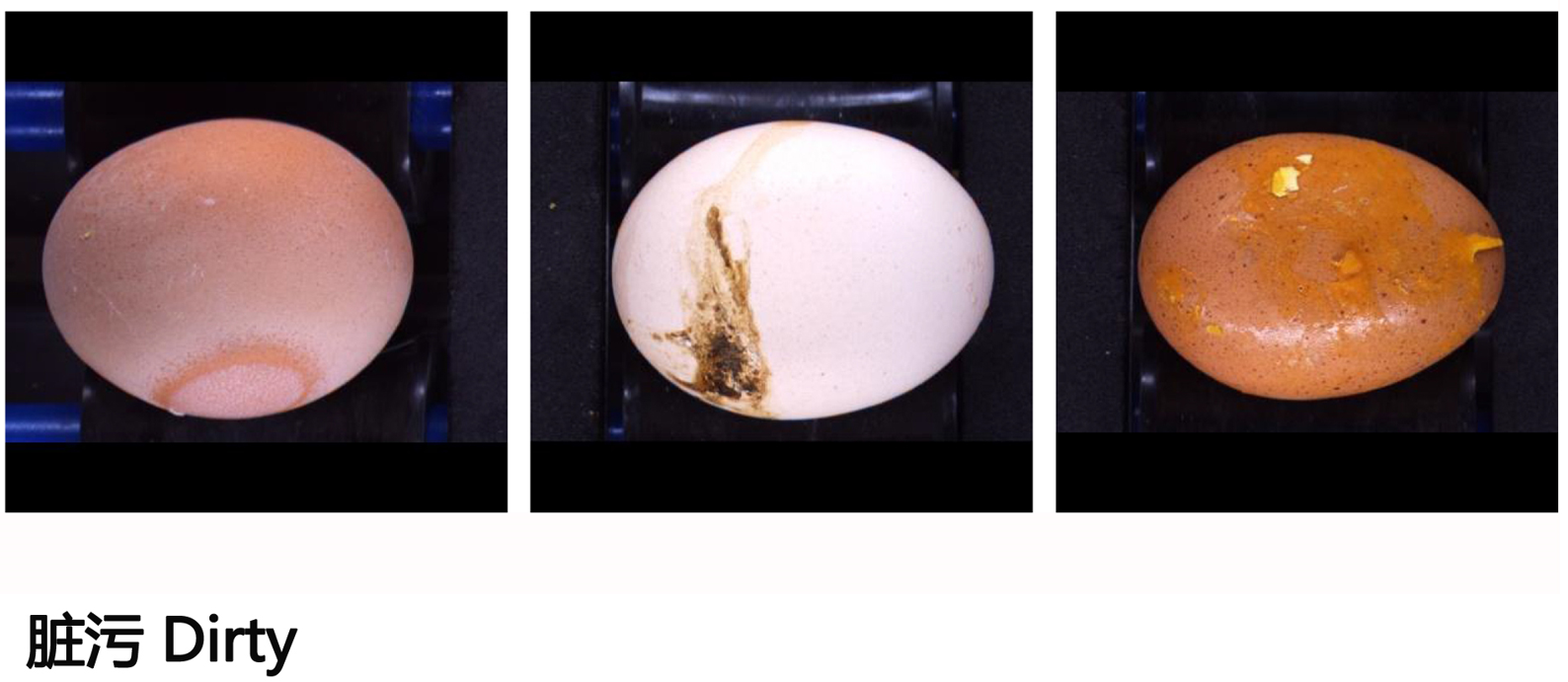

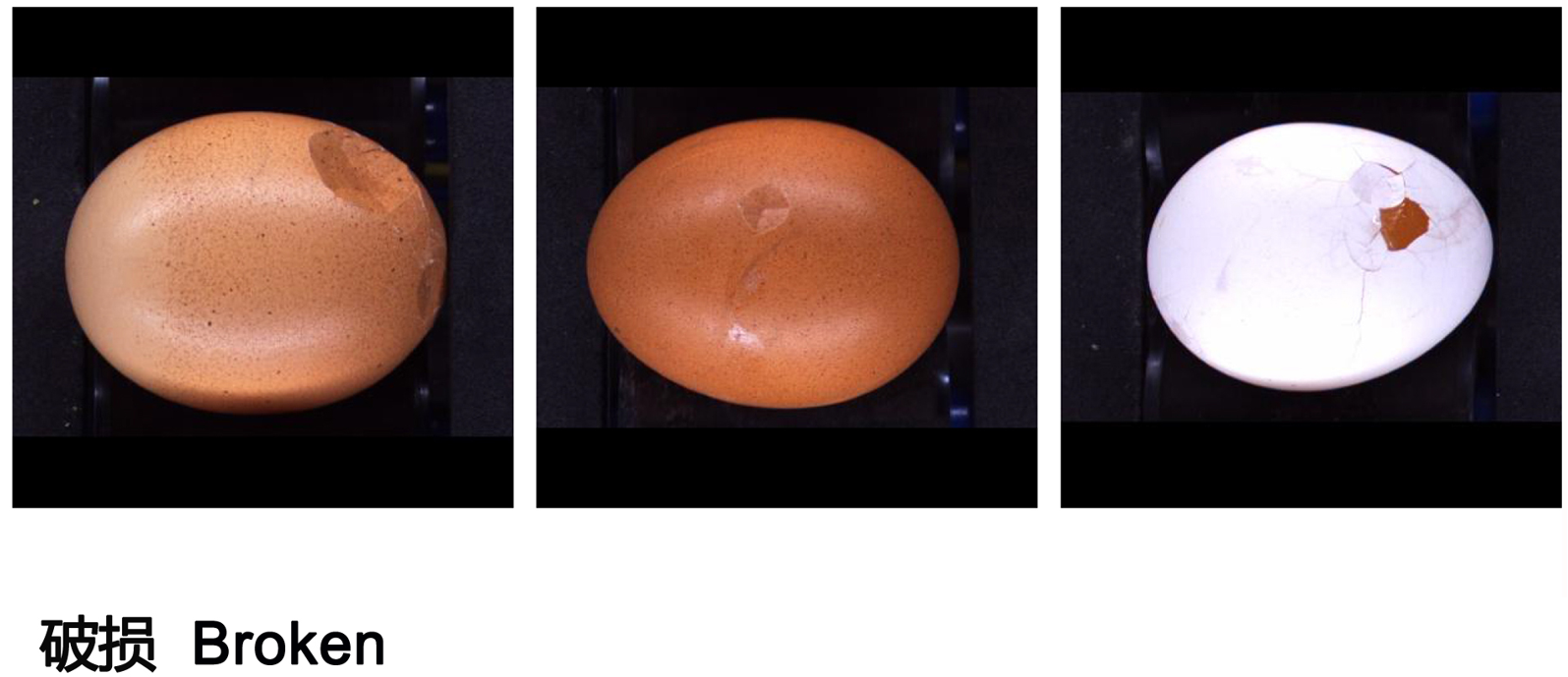

Function: Reject broken, dirt, leak, ugly, oversized eggs

You’ll be redirected to our official online store to complete your purchase. Visit our FAQ to learn more

Details

ZENYER Visual Egg Shell Inspector – Non-Contact Detection System

For many years, manual candling and acoustic crack detection have been the industry standard for identifying cracked eggs. However, these traditional methods can be labor-intensive and carry hygiene risks. Detecting cracks is crucial since eggshells serve as the primary barrier against bacterial contamination — any crack significantly increases the risk of bacterial infection and growth.

The ZENYER Visual Egg Shell Inspector offers a contactless, automated inspection solution that improves food safety and minimizes human handling during egg inspection.

Contactless, Hygienic Inspection

Scans eggs without physical handling, reducing contamination risks and improving biosecurity standards.

AI-Powered Self-Learning Technology

Continuously learns from accumulated data and adapts to new quality standards through ongoing algorithm updates, improving defect detection accuracy over time.

Big Data-Driven Accuracy

Utilizes large historical data sets to enhance defect classification and optimize production efficiency.

Advanced Image Processing

Cameras mounted at the top of the cabinet scan eggs as they rotate on the infeed roller.

White LED light strips provide clear illumination, allowing cameras to capture high-resolution images.

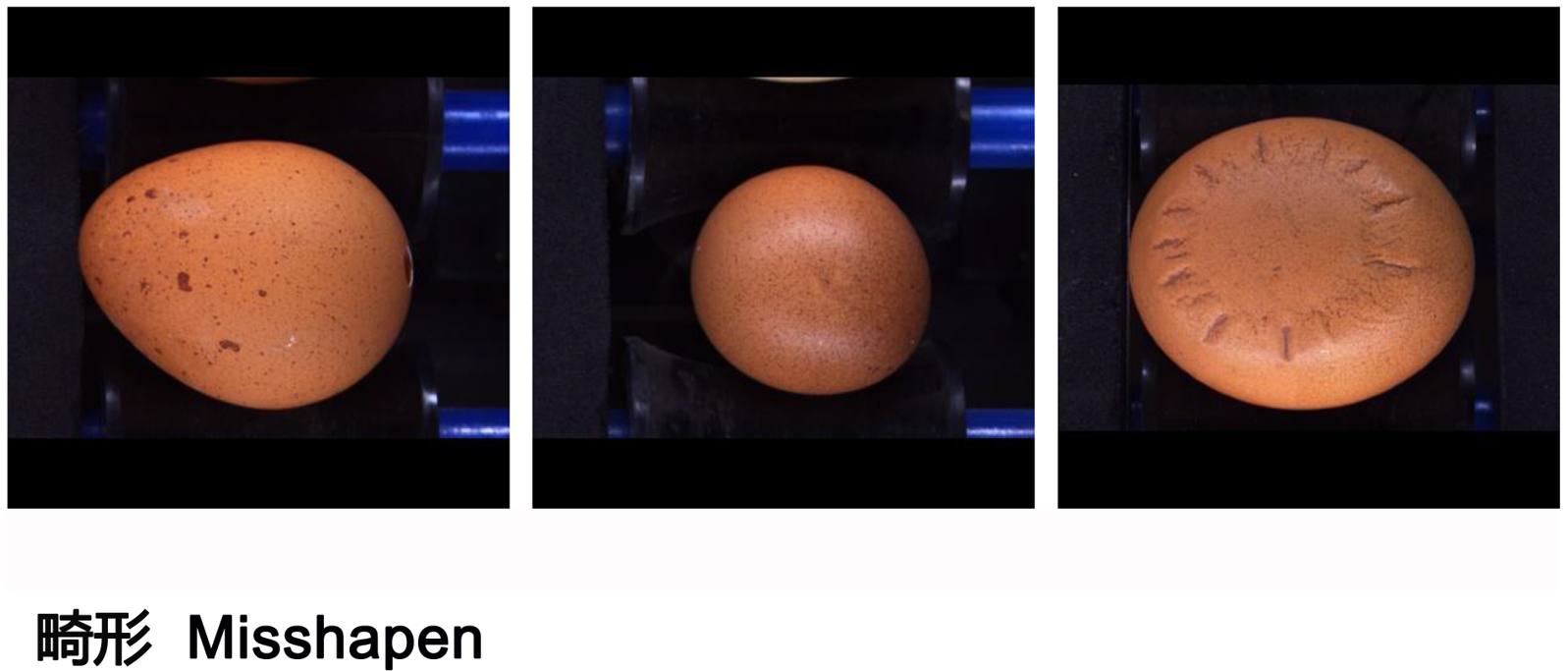

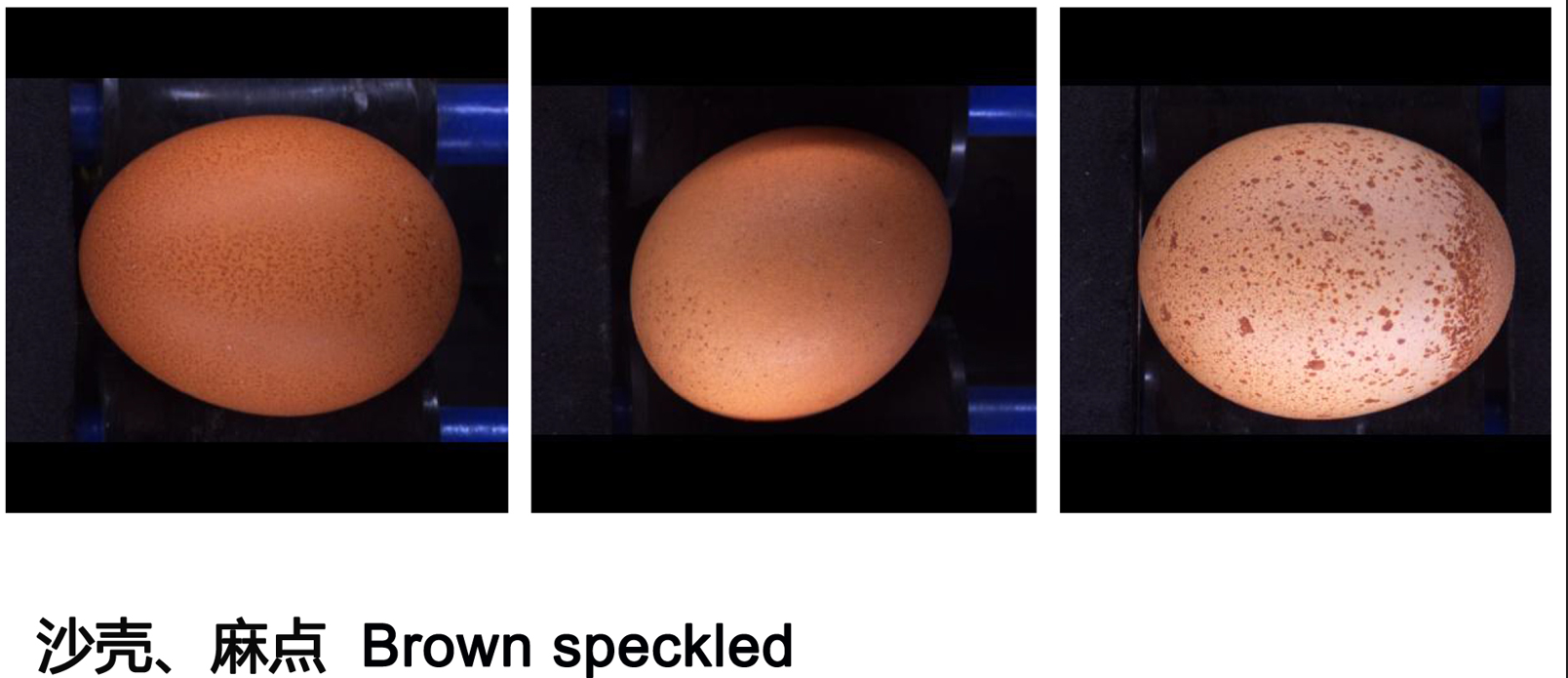

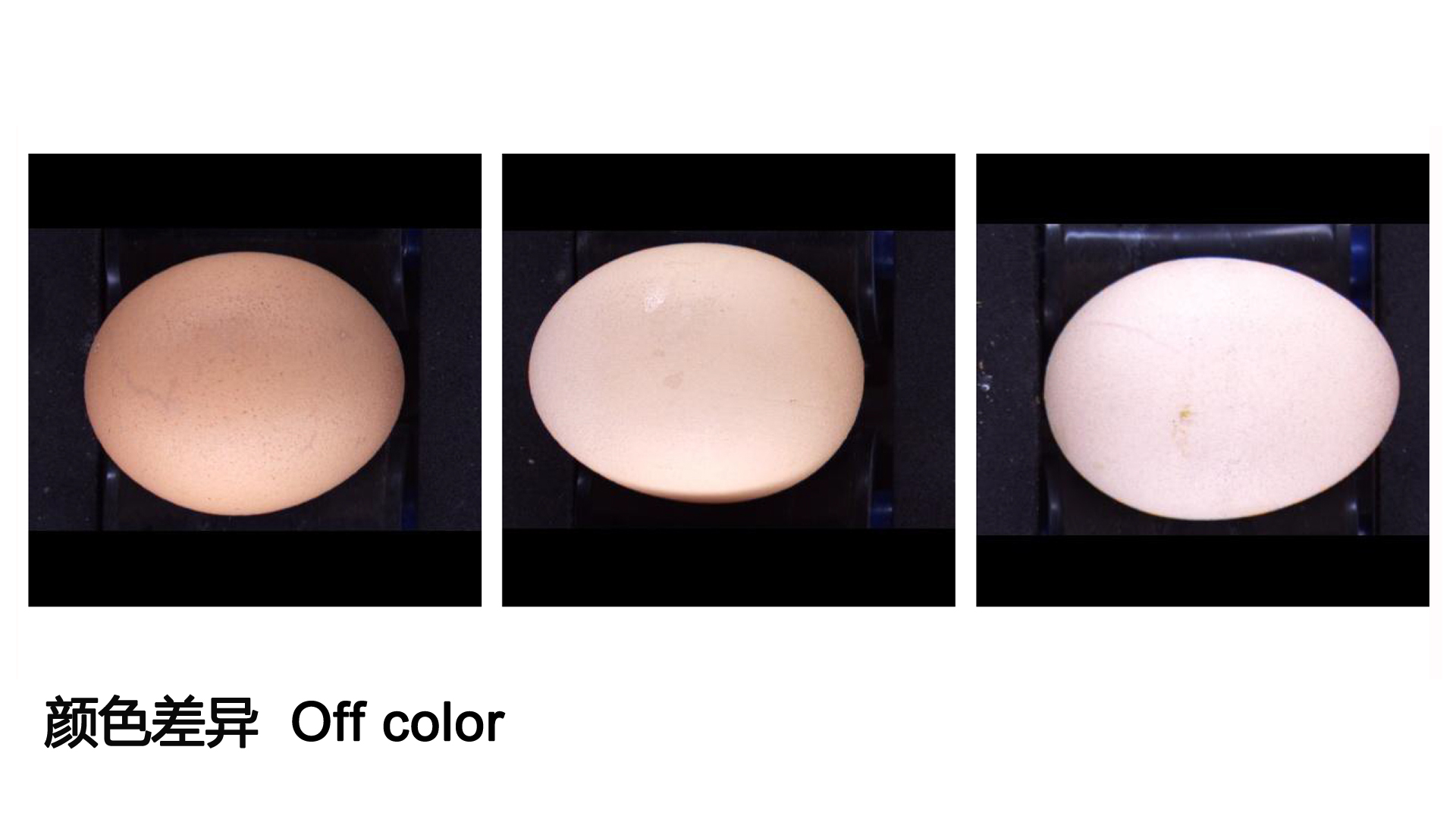

Software analyzes images in real time to identify defects, including cracked shells, leaks, dirt spots, misshapen eggs, off-color eggs, brown-speckled eggs, and other cosmetic defects.

Defective eggs are automatically removed from the line.

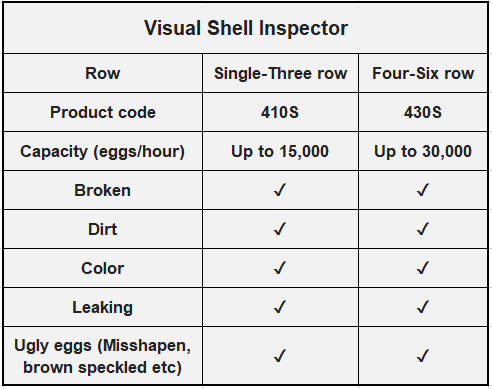

ZENYER 410S & 430S Visual Shell Inspector – Model-Specific Features

Capacity & Compatibility:

410S (Single-Row): Designed for single-row ZENYER egg washers or graders, processing up to 10,000 eggs/hour.

430S (Six-Row): Built for high-capacity systems, handling up to 30,000 eggs/hour.

Modular & Flexible Integration

Can be retrofitted to existing ZENYER graders/washers or other brands of egg graders, washers, and farm packers.

Real-Time Data Monitoring

Displays the number of defective eggs produced per day or per shed, providing valuable insights to optimize flock and farm management.

Customizable Sensitivity

Operators can set specific sensitivity levels for different defect types, allowing a tailored quality-control process.

Remote Monitoring & Maintenance

Includes a remote maintenance system for quick troubleshooting and support, ensuring long-term stable operation.

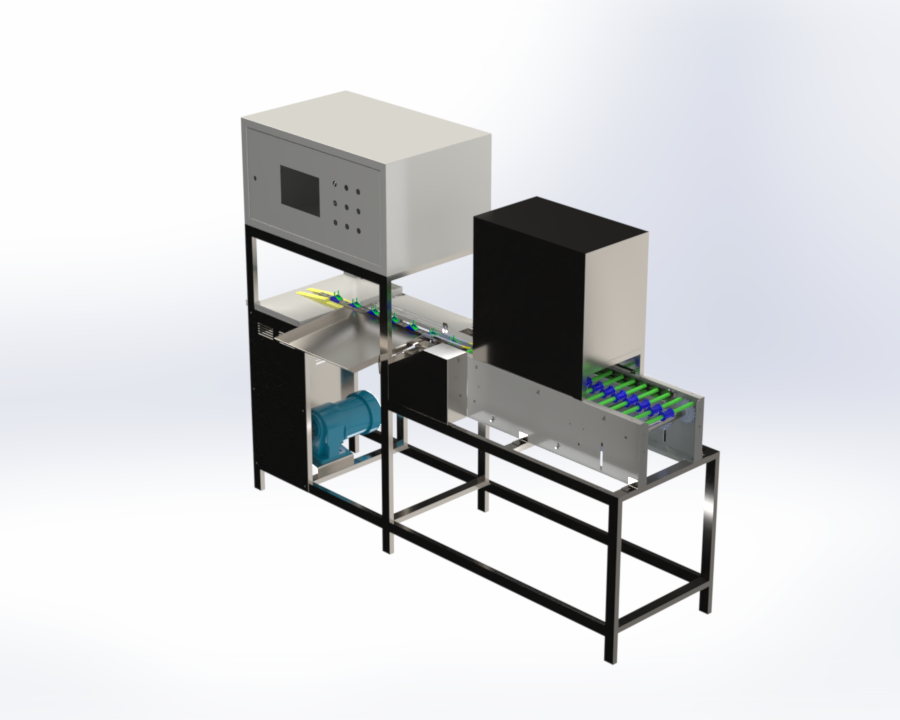

Zenyer 410S (single-row)

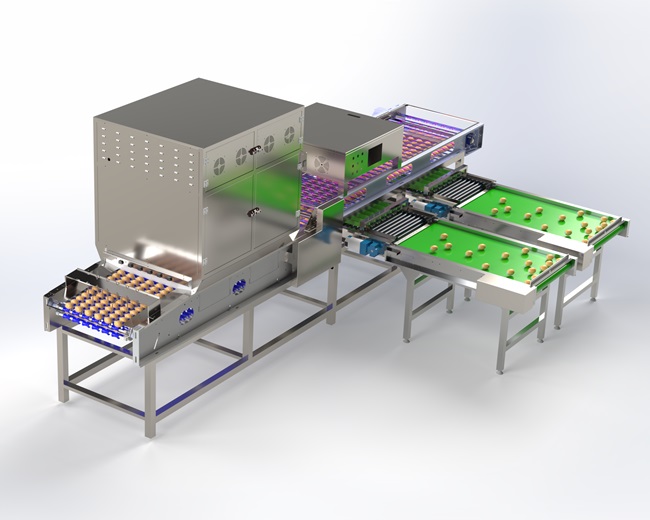

Zenyer 410S (single-row) Zenyer 430S (6-row)

Zenyer 430S (6-row)

Price including GST

(Pre-order)

ZENYER Visual Shell Inspector Brochure