Name: ZENYER Visual AI Detector

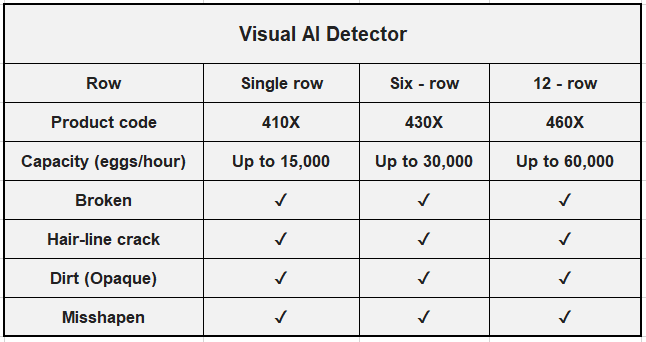

Product Code: 410X/430X/460X

Capacity: 10000/30000/60000 eggs/hour

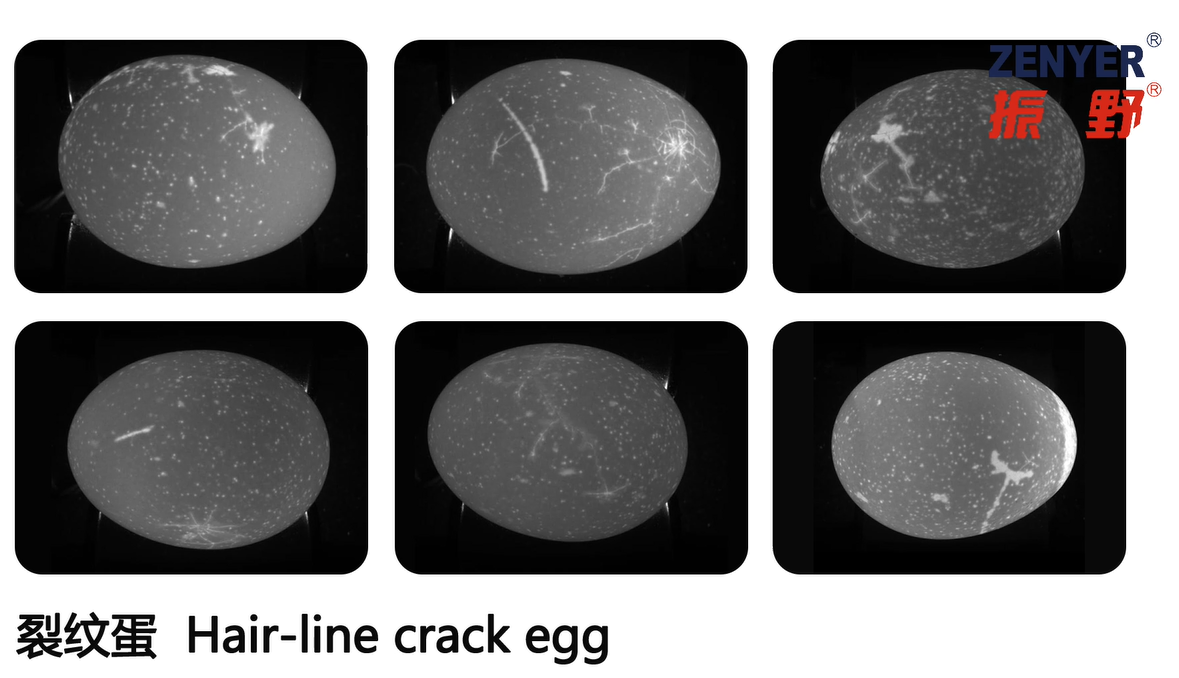

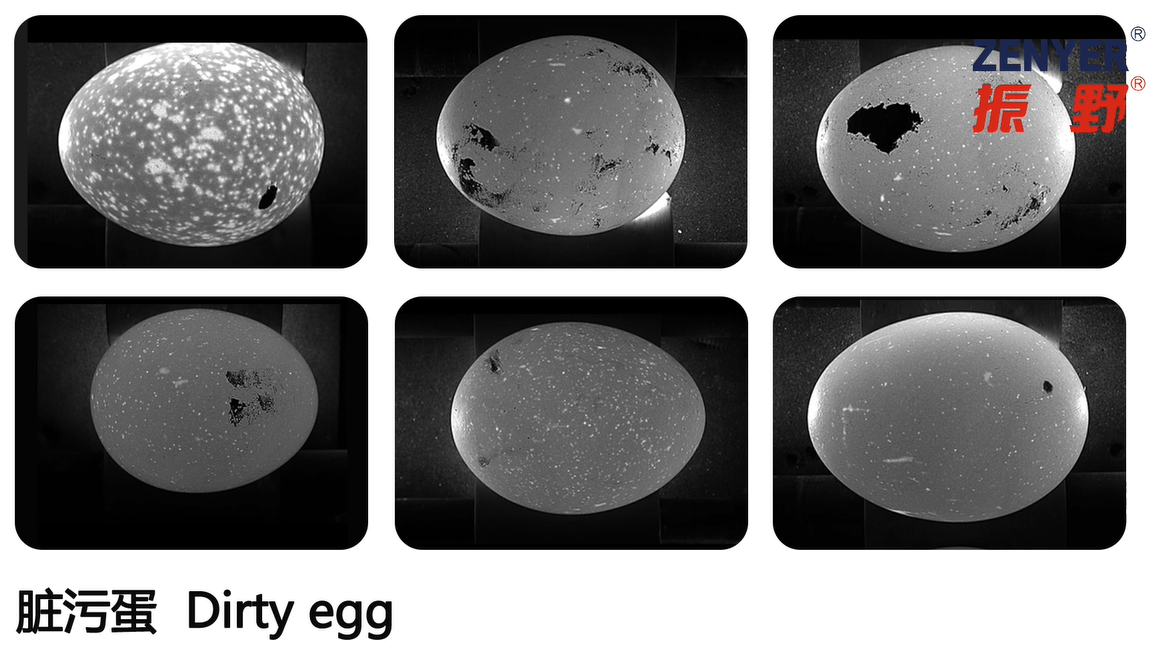

Function: Auto reject dirt, broken, hair-line cracked eggs

You’ll be redirected to our official online store to complete your purchase. Visit our FAQ to learn more

Details

ZENYER Visual AI Detector – Contactless Egg Detection System

For years, manual candling and acoustic crack detection have been the industry standards for egg inspection. However, these traditional methods present hygiene risks and can be labor-intensive. Cracked egg detection is particularly critical because any breach in the eggshell significantly increases the risk of bacterial infection and contamination.

The ZENYER Visual AI Detector offers a contactless, fully automated solution that improves food safety and enhances inspection efficiency.

Contactless, Hygienic Detection

Inspects eggs without physical handling, significantly reducing contamination risk and improving food safety.

AI-Powered Self-Learning System

Continuously learns from accumulated data and adapts to new quality standards and requirements through algorithm updates, improving accuracy over time.

Big Data-Enhanced Accuracy

Uses historical data and image processing technology to enhance defect detection efficiency, ensuring reliable results.

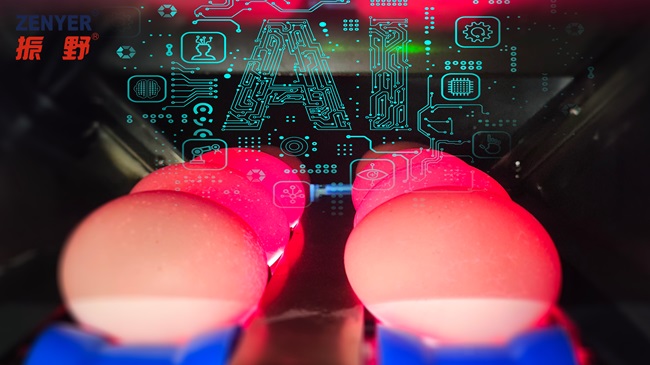

Advanced Image Processing Technology

Cameras mounted at the top of the cabinet scan eggs while they rotate on the infeed roller.

Infrared light strips placed under the roller create clear images, which are analyzed by the system’s computer.

Eggs with cracks, dirt spots, or other defects are automatically rejected, reducing human error.

ZENYER 410X & 430X & 460X Visual AI Detector -Specific Features

Compatibility:

410X (Single Row): Works with single-row ZENYER egg washers or graders, handling up to 10,000 eggs/hour.

430X (Six-Row): Ideal for high-capacity egg handling line, handling up to 30,000 eggs/hour..

460X (12-Row): Ideal for high-capacity egg handling line, processing up to 60,000 eggs/hour.

Modular Design

Can be easily integrated into new or existing ZENYER egg graders, washers, or farm packers — or even third-party equipment.

Real-Time Detection Data

Monitor the number of defective eggs produced per day or per shed, providing valuable data to improve farm management and reduce waste.

Customizable Sensitivity Settings

Set specific sensitivity levels for different defect types (cracks, dirt, etc.) for tailored quality control.

Remote Monitoring & Maintenance

Includes a remote service system that enables real-time troubleshooting and fast resolution of potential issues, ensuring reliable, long-term performance.

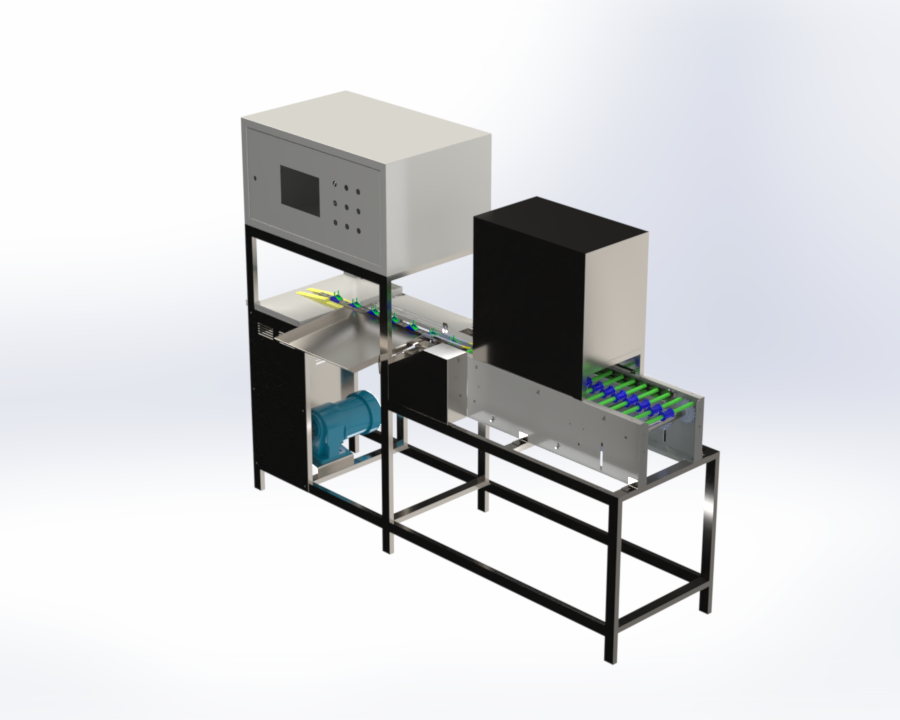

Zenyer 410X Visual AI detector(single-row)

Zenyer 410X Visual AI detector(single-row) Zenyer 410X (single-row)

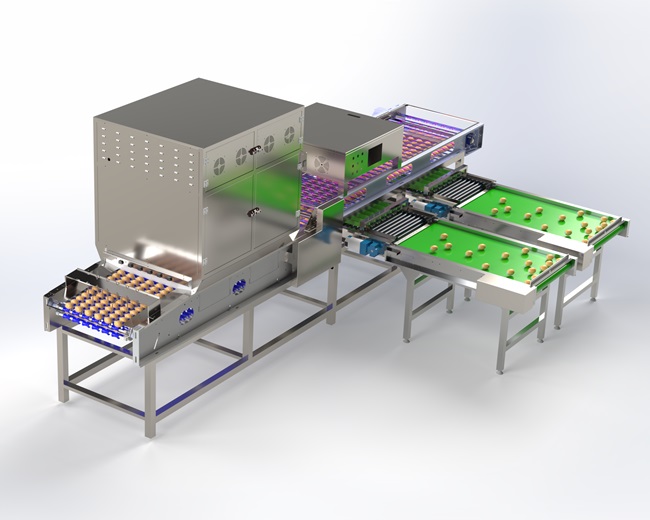

Zenyer 410X (single-row) Zenyer 430X (6-row)

Zenyer 430X (6-row) Near-infrared (NIR) light

Near-infrared (NIR) light

Price including GST

(Pre-order)

ZENYER Visual AI Detector Brochure