Name:ZENYER Visual Shell Inspector

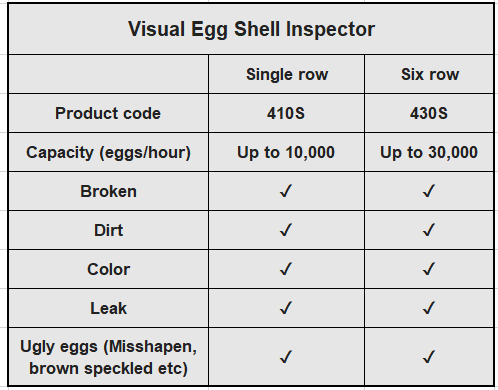

Product Code: 410S/430S

Capacity: 10,000-30,000 eggs/hour

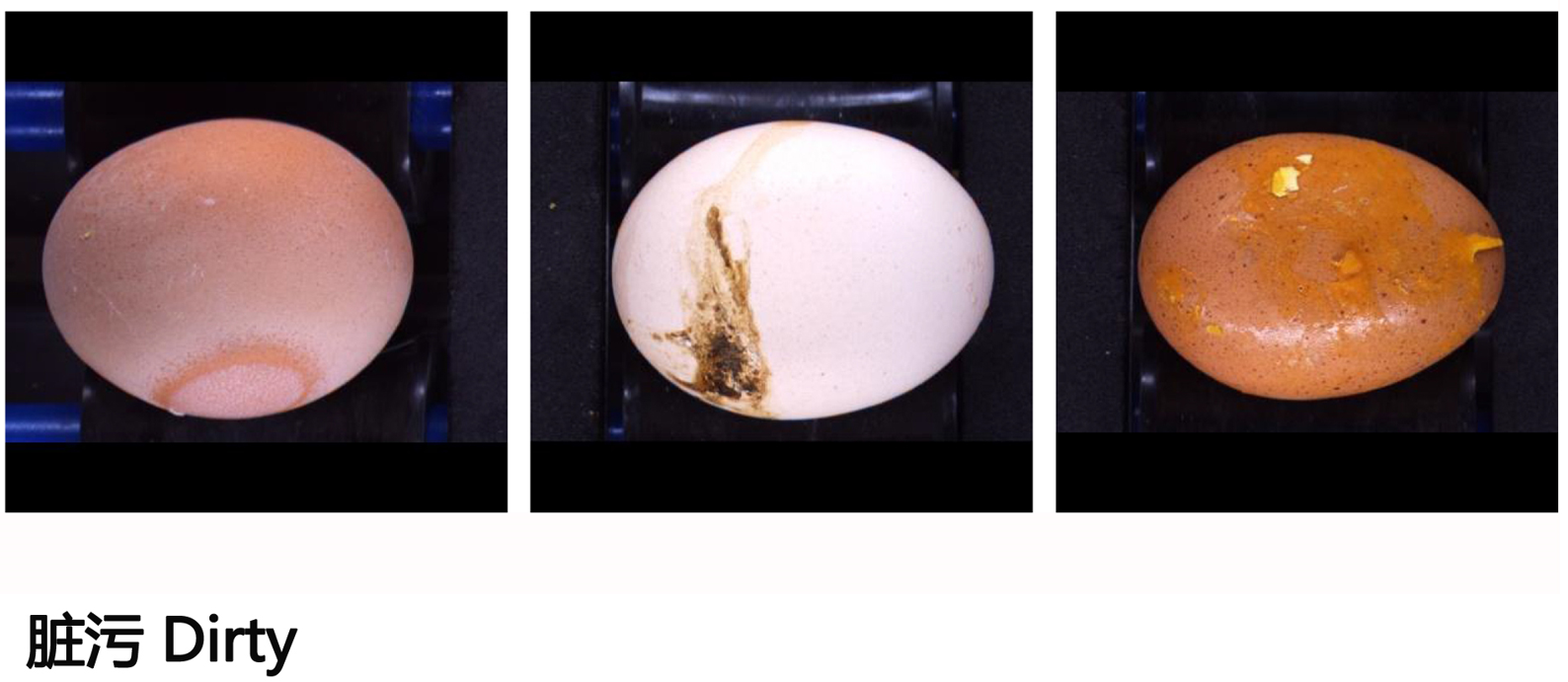

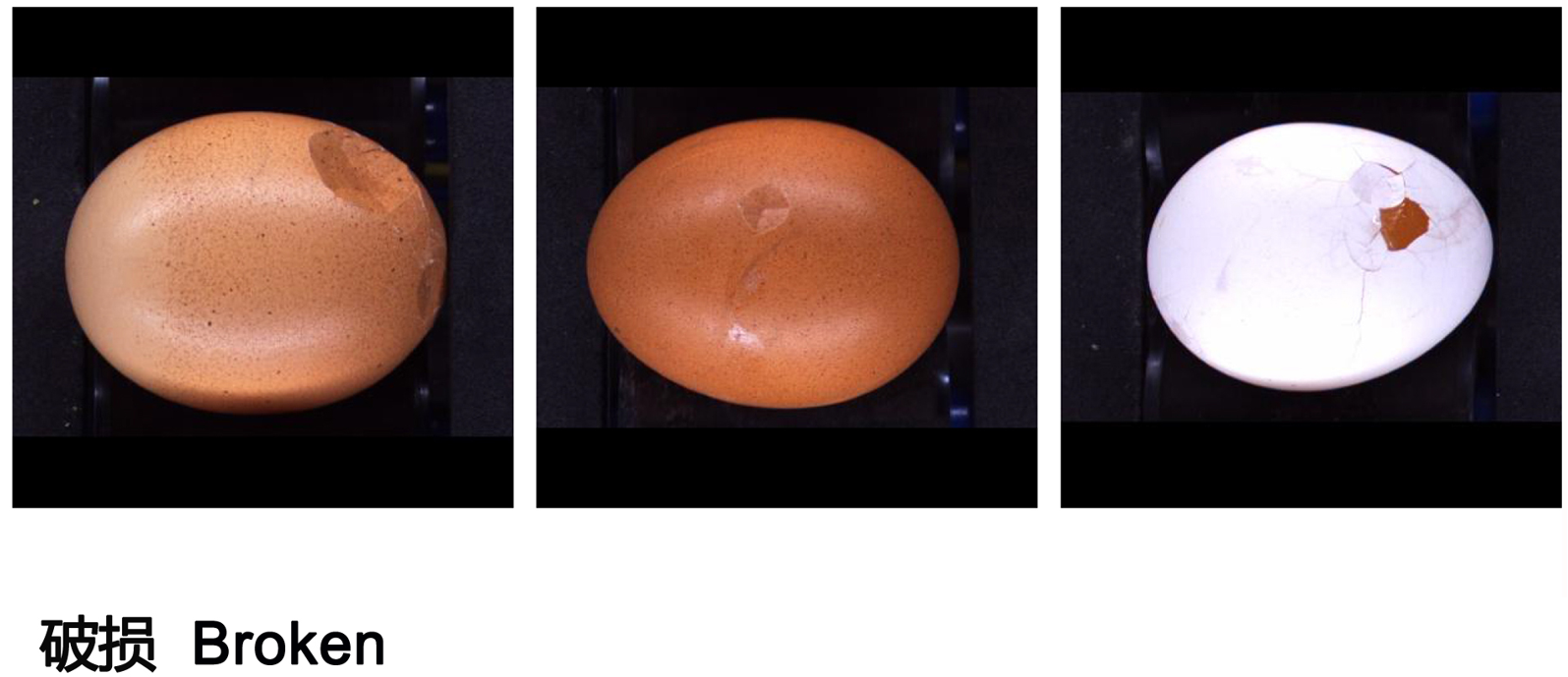

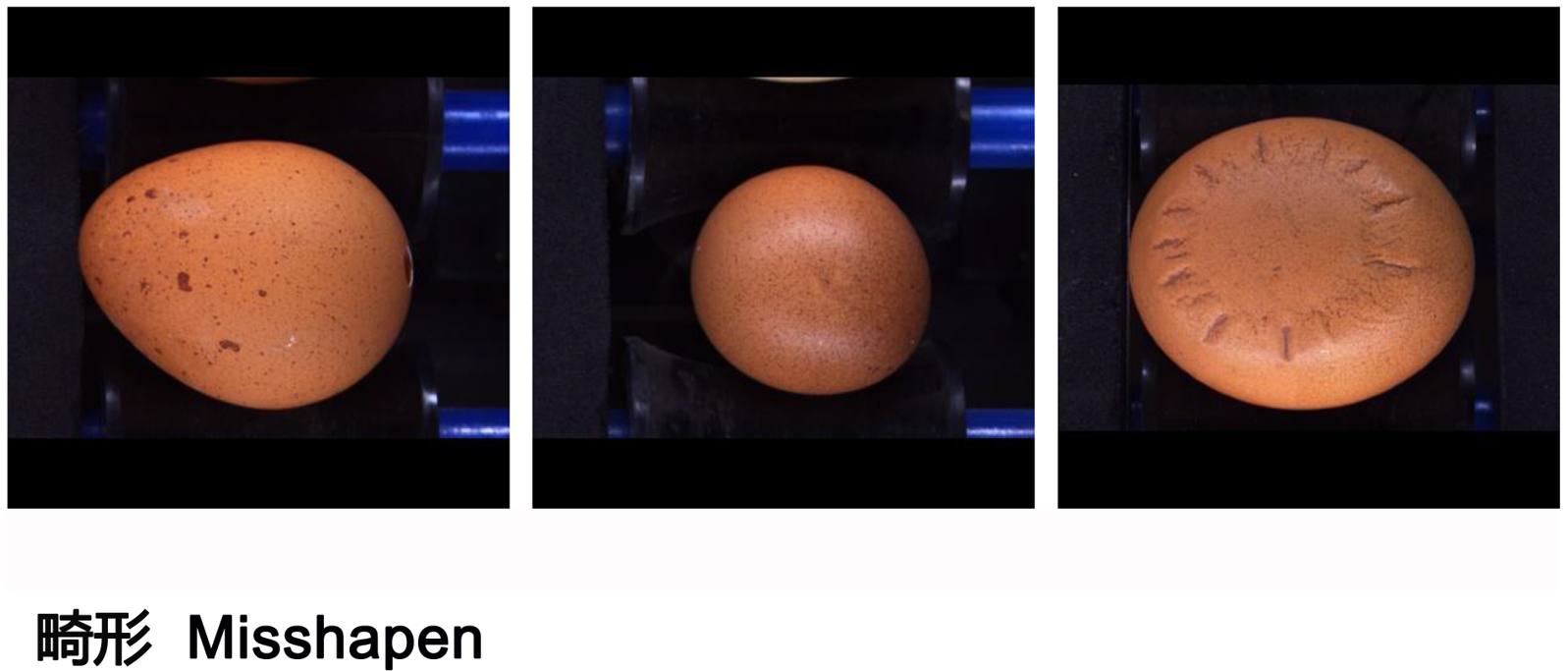

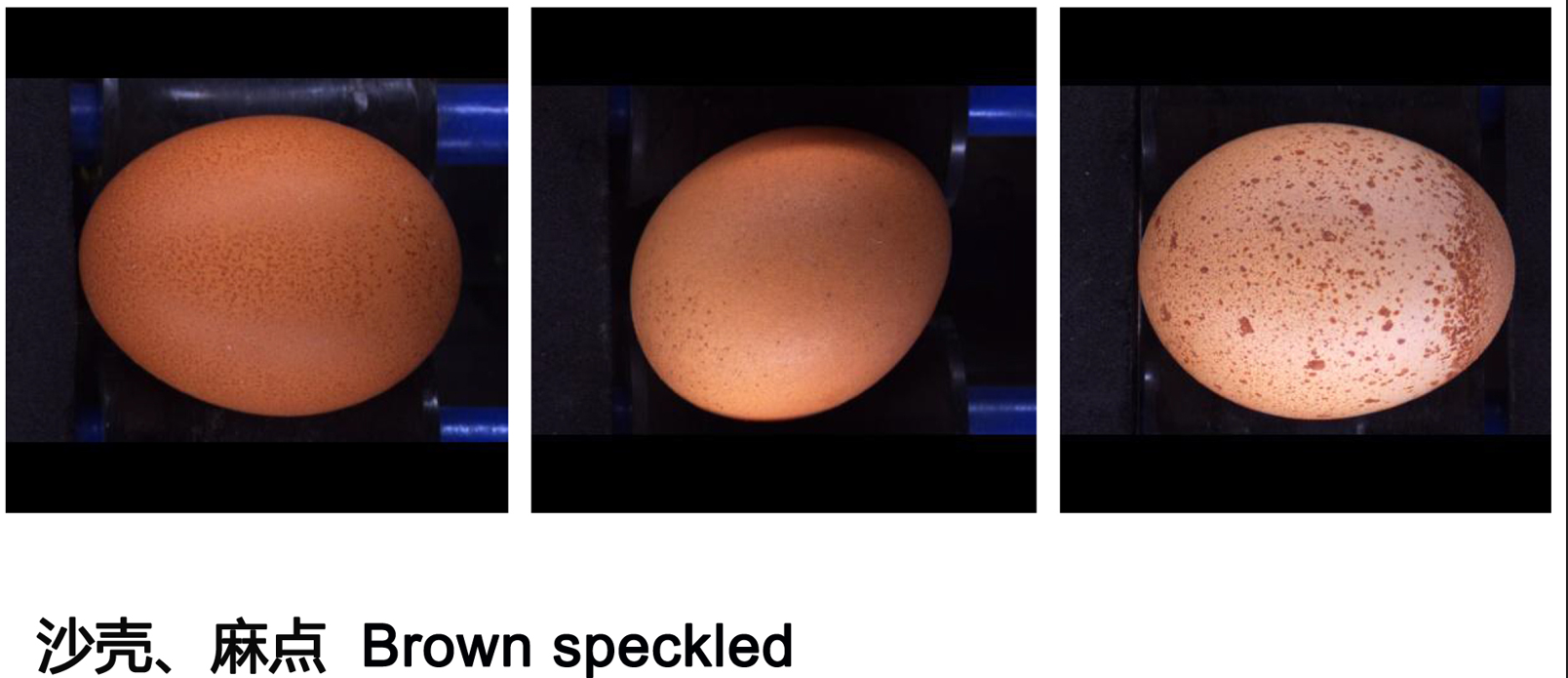

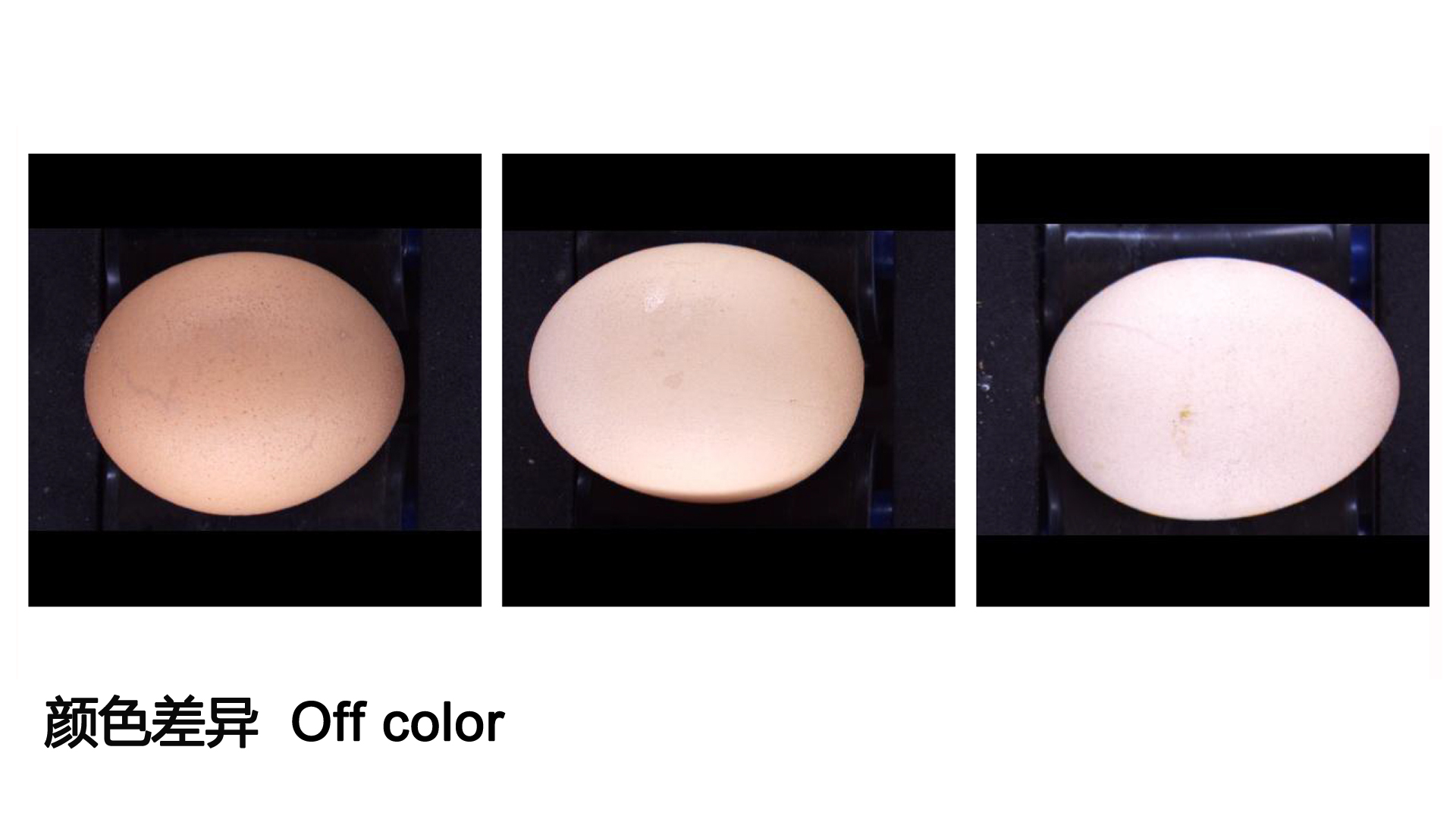

Function: Identify and remove broken, different colour, dirty, leaking and misshapen eggs from the line

Details

ZENYER Visual Egg Shell Inspector - Non Contact Detection System

For many years, the manual candling inspection and acoustic crack detection have been the industry standard for inspecting cracked eggs.

Egg crack detection is an especially vital inspection criterion, since the eggshell forms an important barrier against bacterial growth on the inside of the eggs, any cracks in the shell therefore presents an increased risk of bacterial infection and growth.

In addition, the traditional egg inspection methods, such as manually picking out the cracked eggs or hitting the eggshell with a testing device both have potential hygiene risks.

The Zenyer visual egg shell inspector is contactless, which allows operators to scan the eggs without physically handling them, resulting in even further improvement in food safety and hygiene.

The system has self-learning capabilities to adapt to new standards and requirements through continuous data accumulation and algorithm updates.

Combined with big data technology, the system can learn from a large amount of historical data to improve detection accuracy and efficiency.

The detector works through image processing. Cameras mounted inside the top of the cabinet scan the eggs while they are rotating on the infeed roller. The White Led light strips placed under the roller allow the cameras to take clearer images which are then processed in the computer. Any eggs with broken shells, dirt spots, leak, off color, ugly eggs such as misshapen, brown speckled or any other defective eggs will be rejected automatically.

Features:

Price including GST

(Pre-order)

ZENYER Visual Shell Inspector Brochure